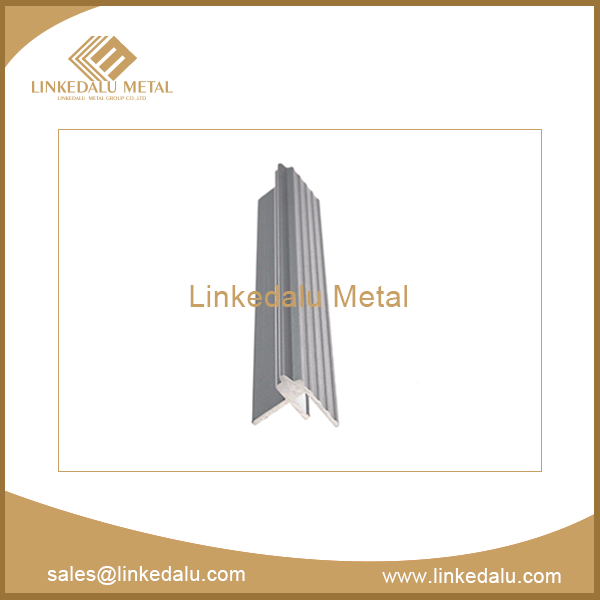

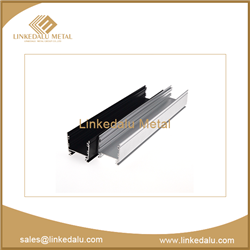

Description:

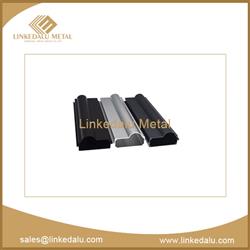

Nowadays, Luggage becomes a necessary part for our life. During our evection, a light-weight, high-capacity luggage will help a lot for our trip. So it’s essential to choose suitable material. And luggage frame aluminum profiles are born, which not only change the whole industry for luggage, but also change the way that people used to live. Aluminum profiles for luggage part is one of the industrial aluminum profiles. As we all know, the unique characteristics make aluminum a widely use profile. And now it goes to the luggage. Aluminum profiles for luggage frame makes the whole luggage harder, which ensures the stability of luggage, and the portability of industrial aluminum profiles help luggage carry more stuffs but less weight. So the luggage frame aluminum profiles become the first choice for luggage material choosing. Our company is the largest Chinese alumina manufacturer for making industrial aluminum profiles. I do believe that our stuff will meet your requirements.

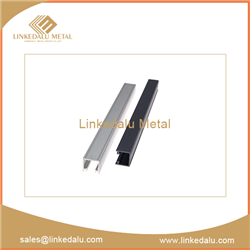

Technical parameters:

Alloy & Temper: 6063-T5

Mechanical properties:

Hardness: 60HBW (Steel balls with a diameter of 10 mm and a load of 500 kg)

Tensile strength: 145~185 MPa

Elongation rate: 12%

Size:

Width: >10mm

height: >5mm

Length: >800mm

Advantages for stuff:

1. Light and consistency, easy installed

2. corrupt-proof, weather-proof, sound-proof and fire-proof

3. excellent smoothness and easy cleaning

4. environmentally friendly and good plasticity

5. Easy to carry during your trip or evection.

Our advantages

1. against Chinese largest alumina mine to keep good material

2. professional engineers and skilled workers

3. one-stop aluminium extrusions and machining parts.

4. professional management to support our customers.

5. cooperating with some global top famous projects contractors

The procedure of procurement

1. Customers send samples or drawings to us to make our drawings

2. Customers confirm drawings and pay for mould costs

3. We need about 20 days to make moulds and send samples to customers approve

4. Customers place order and pay for 30% deposit by T/T

5. It takes about 20 days to finish an order to load container

6. Customers pay for balance to get original documents.

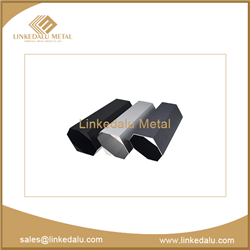

Something You need to Know About Anodized Industrial Aluminum Profile

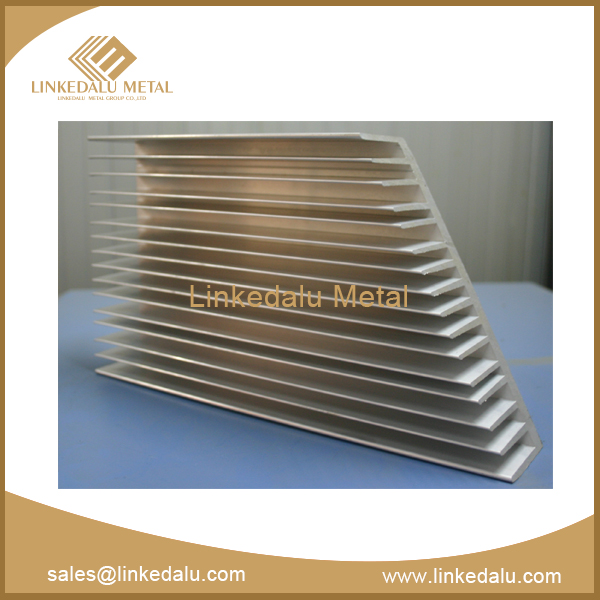

Anodized industrial aluminum profile is manufactured through the process of anodizing. The so-called anodizing is a process in which aluminum or aluminum alloy products are used as anodes, placed in electrolyte solution for electrifying treatment, and the process of forming alumina film on its surface by electrolysis is called Anodized industrial aluminum profile. After anodic oxidation treatment, the surface of aluminum can form several microns -- hundreds of microns of oxide film. Compared with the natural oxide film of aluminum alloy, its corrosion resistance, wear resistance and decorative property are significantly improved. In order to overcome the defects of surface hardness and wear resistance of aluminum alloy, expand the application range and prolong the service life, surface treatment technology has become an indispensable part in the use of aluminum alloy, and the anodizing technology is the most widely used and most successful. As an aluminum alloy profile produced by special surface treatment process, Anodized industrial aluminum profile has its unique application. When the industrial aluminum profile is used outdoors, a protective film will be formed on the surface of Anodized industrial aluminum profile after anodizing treatment, which makes it not easy to be oxidized and corroded, and can prolong its service life. At the same time, it also ensures the appearance and is not easy to wear and paint. Part of Anodized industrial aluminum profile will also be applied to electronics, as hard disk shell, radiator, etc. After anodizing, the surface of Anodized industrial aluminum profile is not conductive and can also protect the circuit. In addition, some aluminum products can also be used for oxidation font, as the outer packaging, the use is very much. In addition to these application scenarios, the advantages of Anodized industrial aluminum profile can be attributed to the following five points:

1. Corrosion resistant alumina film is a dense and transparent protective film. The chemical properties of alumina are stable and very corrosion resistant. The oxide film of pure aluminum is even more corrosion resistant than that of aluminum profile.

2. The oxide film on the surface of Anodized industrial aluminum profile is higher than that on the aluminum substrate itself, which can protect the aluminum profile. Moreover, the oxide film also plays a role of wear resistance. The porous oxide film on the surface has the ability of absorbing lubricant, which makes the surface of industrial aluminum profile more wear-resistant.

3. The anodic oxide film of industrial aluminum profile is not metallic material, and alumina is not conductive, which is a good insulating material. It is especially suitable for some electronic and electrical equipment manufacturers.

4. The thermal conductivity of anodic oxide film is much lower than that of aluminum profile substrate. The alumina film can withstand high temperature up to 1500 ℃, while the aluminum profile substrate can only withstand 660 ℃.

5. The anodic oxide film of industrial aluminum profile is porous structure and has strong adsorption capacity. Therefore, the protection, insulation, wear resistance and decoration properties of aluminum products can be further improved by filling the holes with various pigments, lubricants and resins.

All Products

All Products

Industrial Profiles

Industrial Profiles

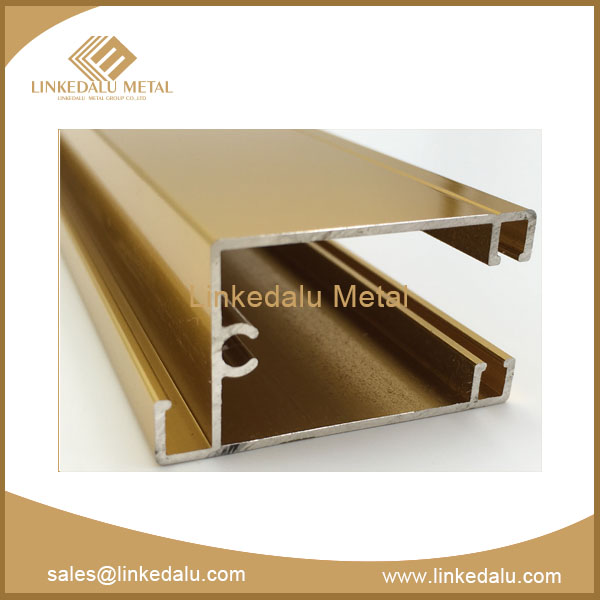

Curtain Wall Profiles

Curtain Wall Profiles

Windows and Doors Profiles

Windows and Doors Profiles