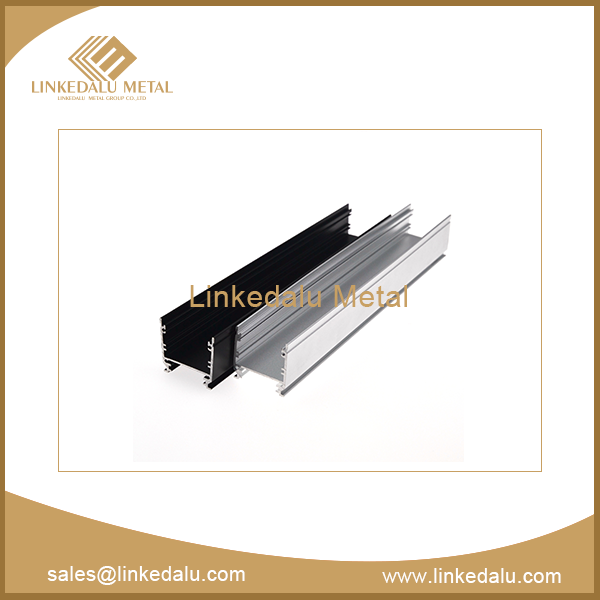

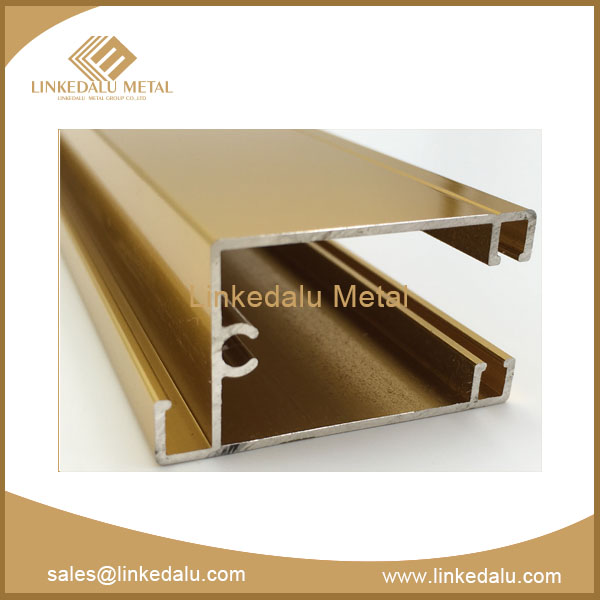

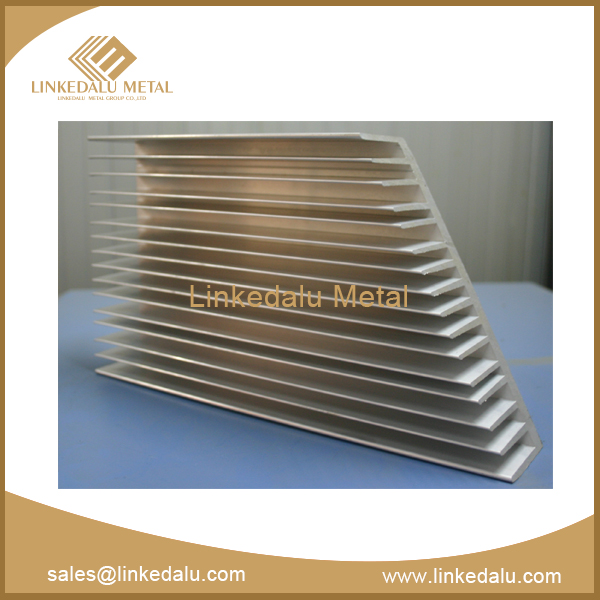

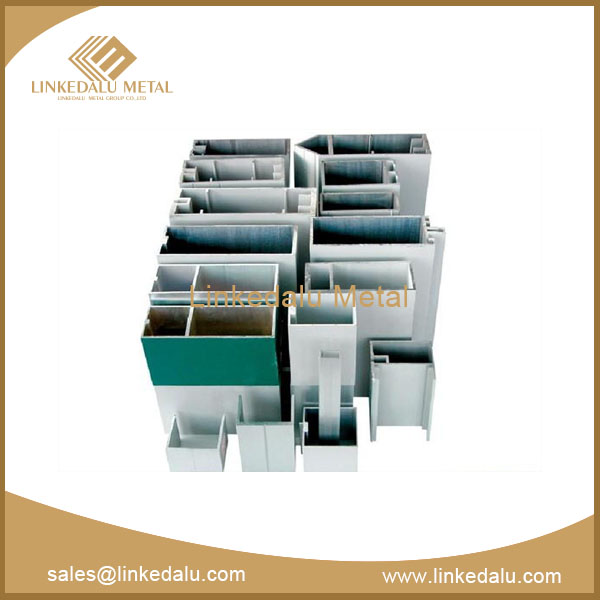

An important part of any linear LED luminaire – the aluminum profile housing – is a durable, lightweight enclosure for LED strip lighting in any color, temperature or output. Importantly, they are the primary source of thermal management for LED strips. They come in many different styles to create any lighting effect based on your design goals. We are able to offer a wide range of LED aluminum profile housings, including industrial aluminum profile for surface mount LED strip illumination, flush mounted LED strips, high output LED illumination, suspension/cable mounted LED strip illumination, and more. We are also an aluminium extrusion suppliers. Custom application. Some custom applications include embedded linear LED lighting for concrete in driveways, or LED strip lighting for stair pedals between wall tiles. The LED lamp housing is made of a blister acrylic sheet, which absorbs light evenly, so the light emitted through the acrylic sheet is soft and the color is pure. The function of the LED lamp housing is that it not only covers the lamp to make the light gather together, but also prevents static electricity and also has a role in protecting the eyes, so each lamp has a lamp housing. Include aluminum framing system.

Aluminum compared to stainless steel

Today's high-power LED lamps are generally made of aluminum, and the strength of aluminum alloy profiles is cast aluminum, aluminum, and aluminum. Compared with stainless steel, it has the following advantages:

1. LED lamps need to dissipate heat What is a good material for heat insulation breaking bridge, and aluminum has much higher thermal conductivity than steel;

2. the aluminum surface has a layer of dense alumina, which has good anti-oxidation and corrosion effects;

3. later, aluminum is cheaper than stainless steel, and the price is right.

The LED aluminum substrate is the PCB, which is also the meaning of the printed aluminum circuit board. The circuit board material is the aluminum alloy LED lamp. The circuit board is generally an aluminum substrate, which can conduct heat quickly. The circuit board for other equipment or electrical appliances is still glass. MDF. Everyone knows about LED aluminum substrates. Generally, what are the applications? Let's take a look at it.

The application fields of LED aluminum substrates are mainly applied to the following equipment:

Audio equipment: input, output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc. The substrate conventional aluminum profile balcony bracket can be used as a PCB for LED lighting fixtures. We are interested in knowing more about aluminum substrates. Aluminum substrate is made of aluminum alloy. Its thermal, electrical and mechanical properties are especially important. Common parameters such as specific heat capacity, thermal conductivity, melting point range, linear expansion coefficient, electrical conductivity, electrical resistivity, hardness, fatigue strength and tensile strength. elastic modulus, elongation, cutting force, etc. In the case of national standards, thermal conductivity is especially important. Our company is a professional aluminium window suppliers and aluminium pipe suppliers.

Hope our products will satisfy you.

All Products

All Products

Industrial Profiles

Industrial Profiles

Curtain Wall Profiles

Curtain Wall Profiles

Windows and Doors Profiles

Windows and Doors Profiles