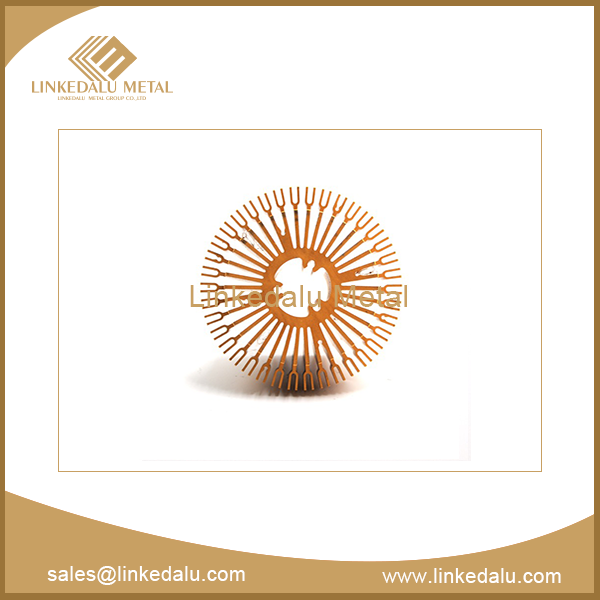

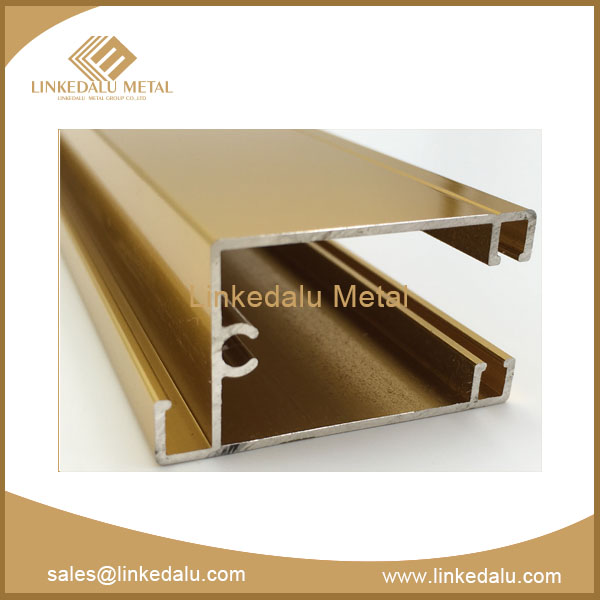

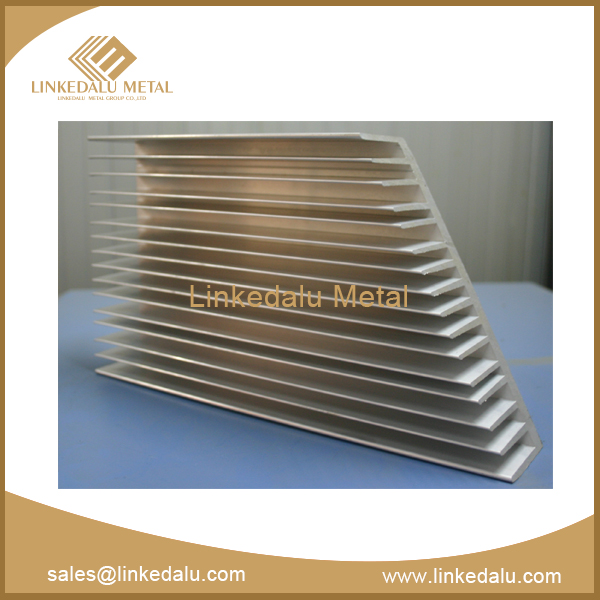

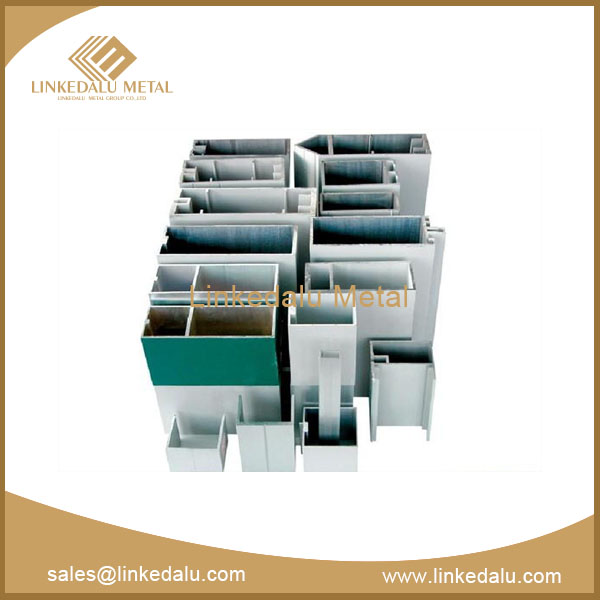

There are three main types of aluminum alloy radiator profiles: flat and wide, comb or fishbone; circular or elliptical outer fins are radial; The common feature is that the distance between the fins is short, and a groove shape is formed between the adjacent fins, and the aspect ratio thereof is large; the wall thickness difference is large, the fin is generally thin, and the bottom plate of the root has a large thickness. Therefore, it is very difficult to design, manufacture and produce the mold of the heat sink profile. Radiator profiles are smaller in size and symmetrical in shape, making them easier to produce. Most of the heat sink profiles are flat and wide, the outer dimensions are large, some are asymmetrical, and the groove shape width between the heat sinks is large, which is difficult to produce. Include aluminum framing system and aluminum curtain wall. It is necessary to cooperate with the ingot, mold and extrusion process in order to successfully produce qualified radiator profiles. The aluminum profile of the radiator has the advantages of beautiful appearance, light weight and good heat dissipation performance, and has been widely applied and developed in aerospace, rail transit, construction engineering and other industries. However, due to its shape, such as long cantilever length, small tooth spacing, and large tongue ratio, in the actual production process, the success rate of the test product of this type of product has been low, and it is often necessary to repeatedly test the mold and repair the mold to meet the production requirements. We are also an aluminium extrusion suppliers. Therefore, it is necessary to study the forming of the aluminum profile of the radiator. Aluminum is a metal material used in the automotive industry and is the preferred material for lightweight vehicles. The biggest advantage of aluminum is its light weight, the specific gravity is only one-third of that of copper. Under the same volume, the quality can be greatly reduced. The aluminum radiator profile is easy to process, and can be extruded into various tubular shapes with new appearance, which is in line with the current civil building decoration and decoration function. Now extruded aluminium sections is very common. Domestic car radiators are still dominated by copper radiators, which are widely used only in small engines such as cars. Since the introduction of the first aluminum water tank production line in 1992, China has introduced a number of production lines, starting with mechanical assembly and later introducing a brazing process line. However, compared with foreign countries, the overall production process is backward and production efficiency is low. Include aluminum framing system and aluminum curtain wall.

©Copyright ©2020 LINKEDALU METAL GROUP CO.,LTD.Technical support:Guangzhou Jumi Network

All Products

All Products

Industrial Profiles

Industrial Profiles

Curtain Wall Profiles

Curtain Wall Profiles

Windows and Doors Profiles

Windows and Doors Profiles