Q: What is the nature of your company?

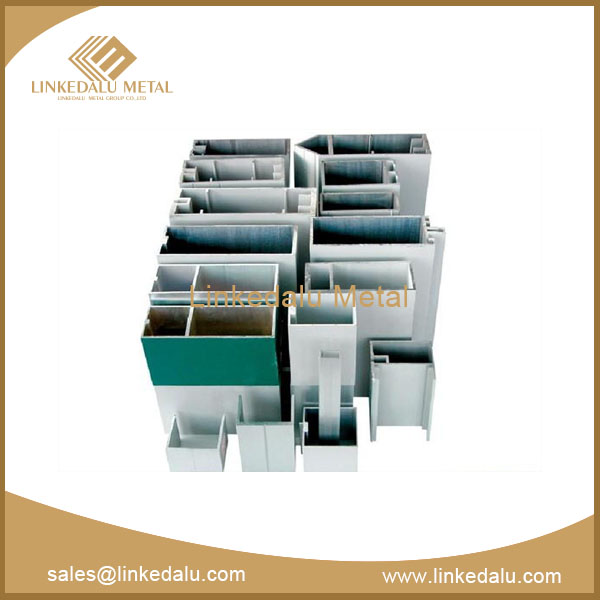

A: We are a company specializing in the production of industrial aluminum profile. Also is a aluminium window manufacturers and aluminium pipe manufacturers. established in 2000.

Q: How long do you have to complete an order?

A: We will complete an order within 30 days of receiving the deposit.

Q: What kind of payment method do you use?

A: 30% deposit, 70% see the copy of the bill of lading.

Q: What is the specific process after ordering?

A: 1. we will make our drawings according to your drawings or samples that have to sent to me by DHL, and send to you confirm.

2. we will send mould cost to you and you arrange 100% mould cost to us by T/T

3. we will produce moulds while we receive the mould cost. it needs about 20 days to send samples to you confirm.

4. you confirm the samples and we will control the quality according to approved samples.

5. you place order to us and I will make a pro forma invoice to you.

6. you approve the pro forma invoice and arrange 30% deposit to us by T/T

7. when we receive the deposit, we need about 30 days to finish the order, I will send you invoice to you and you pay for 70% balance by T/T, and we load container.

Remarks.

1. we can discuss how to package.

2. MOQ, each profile is over 500kgs, each order is a full 20’ container that is about 12 tons, maximum length is 5.85m

3. we can discuss more technical requirement if you have, to keep away any mistake.

Q: What are the characteristics of traffic aluminum?

A: 1. Light weight

When the specific gravity of aluminium (2.7g/cubic centimeter) is observed, the potential of aluminium as a weight-reducing material becomes obvious, which is less than half that of iron (7.8g/cubic centimeter) and copper (8.9g/cubic centimeter).

2. Security

Safety is the most important factor in vehicle design and customer selection. In the development of body structure, the most important thing is to find a suitable compromise between stiffness, crashworthiness and further body requirements (such as shape and packaging restrictions). We are also an aluminium extrusion suppliers. It includes aluminium frame system and aluminium curtain wall. Aluminum is very suitable for achieving these goals with the lowest possible quality and the highest performance.

3. Multifunction

The most important advantage of aluminium is its easy-to-form, lightweight and cost-effective structure. Using different methods from high productivity stamping process to low die cost technology, precise sheet metal can be formed effectively, thus realizing small batch production. Extruding aluminium profiles is very common nowadays. An interesting aspect compared with competitive materials is that extruded, open and closed profiles with different wall thicknesses have complex shapes. Mesh and near-net aluminium parts can be produced by forging and other large-scale forming technologies, but especially by various casting processes.

4. Cost-effectiveness

With the application of aluminium in light vehicles by automobile manufacturers, more and more attention has been paid to the analysis of system cost and life cycle cost in order to achieve the expected results of improving driving performance, reducing fuel consumption or reducing emissions. Manufacturers are increasingly considering how to make full use of the weight reduction of one or more components and allow this weight reduction to provide further weight or cost savings in other vehicle components.

5. Recyclable

Aluminum from transport applications is part of an established recycling system. Recycled aluminium can be used in almost all applications, protecting raw materials, reducing emissions and leading to considerable energy saving. At present, metal and aluminium are the most important and play an important role in financing the end of automobile life through their high waste value.

6. Fashion

In the past two centuries, it is not surprising that some of the most fashionable cars (actually buildings, consumer goods, fashion goods and accessories) have adopted aluminium, because aluminium is not only functional, but also aesthetic; its durability, formability and extensive fineness. HES. Airflow trailers, London's Eros, Philip Stark's 1006 chairs, iPod, BMW 328 racing cars - all make full use of aluminum's lightweight, strength and durability, while transforming from functional objects to cultural icons through its stylish appearance and feel.

7. Durable.

Aluminum, even unpainted and unpainted, can resist the corrosion of water and road salts, and in non-cosmetic key components, the use of aluminium can avoid the huge additional costs of galvanizing, painting and painting some competitive materials. Aluminum will not rust if there are scratches or notches in the paint. Nor does it weaken or become brittle due to desert heat, northern cold or ultraviolet radiation in sunlight.

Q: What is the development trend of traffic aluminum?

A: Transportation aluminum covers a wide range, not just all-aluminum passenger cars, this is only a small piece. The future development trend of aluminum for transportation generally includes the following parts: aluminum for aviation and aerospace, aluminum for rail transportation, and aluminum for automobiles.

Aluminum aluminum for ships is an ultra-high-strength deformed aluminum alloy that is widely used in the aviation industry. It has good mechanical and processing properties, good plasticity after solution treatment, good heat treatment strengthening effect, generally high strength below 150 ° C (or even higher), good toughness, is an ideal structural material. In addition, aviation aluminum is light in weight and light in weight, and has replaced steel and occupied the leading position of current aviation materials. Aviation equipment has higher requirements for aluminum and is an important high-end application market for aluminum.

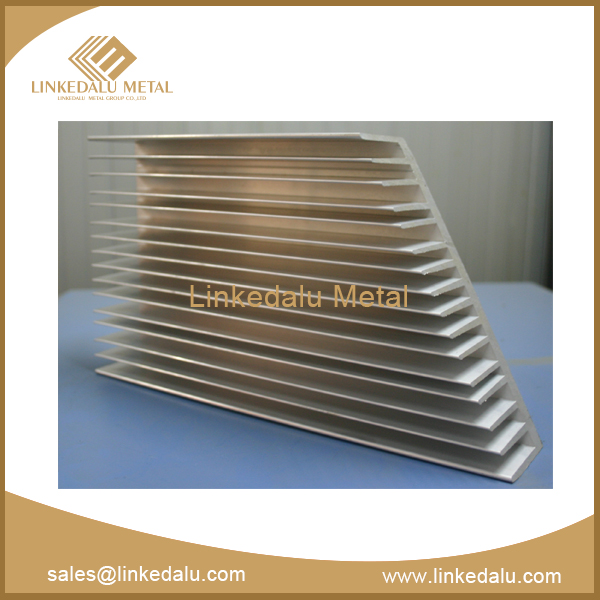

In the construction of the main locomotive and ancillary facilities of the rail transit, a certain amount of aluminum is required. Among the aluminum materials used, extruded industrial aluminum profile are mainly used, accounting for 76% of the total aluminum materials. Other aluminum materials (plates, foils, tubes, rods, forgings, castings, composites, foams, etc.) account for 24%. Include aluminum framing system and aluminum curtain wall.

In addition to the structural parts, aluminum is also used to manufacture functional components, such as aluminum foil components for heat dissipation systems, foam aluminum panels for sound insulation, and aluminum-plastic composite panels for decoration. Rail transit mainly includes two categories of high-speed rail and subway. We are also an aluminium extrusion suppliers.

Aluminum for automobiles is the main consumption direction of aluminum for transportation. The average aluminum consumption per vehicle in China is only 105 kg, and that in Europe and America is 140-150 kg. It is expected that the amount of aluminum used in China will increase by 10%~12% in the next year. With the increasing environmental pollution and energy crisis, reducing vehicle weight and reducing fuel consumption have become an important direction for the green development of the automotive industry. According to relevant statistics, the weight of the passenger car is reduced by 10%, and the fuel consumption will be reduced by 6% to 8%. It can be seen that the lightweight of automobiles has great significance, which not only can alleviate the energy crisis to a certain extent, but also contribute to the control of environmental pollution.

Industrial industrial aluminum profile have been used in the shipbuilding industry for nearly a hundred years. With the rapid development of the shipbuilding industry at home and abroad, the lightweight of ships is increasingly being taken seriously. Now extruded aluminium sections is very common. Due to its low density, high strength and high corrosion resistance, aluminum is very suitable for the harsh environment of the ocean. The processing cost of aluminum is lower, so it is more economical to use aluminum to manufacture ships.

All Products

All Products

Industrial Profiles

Industrial Profiles

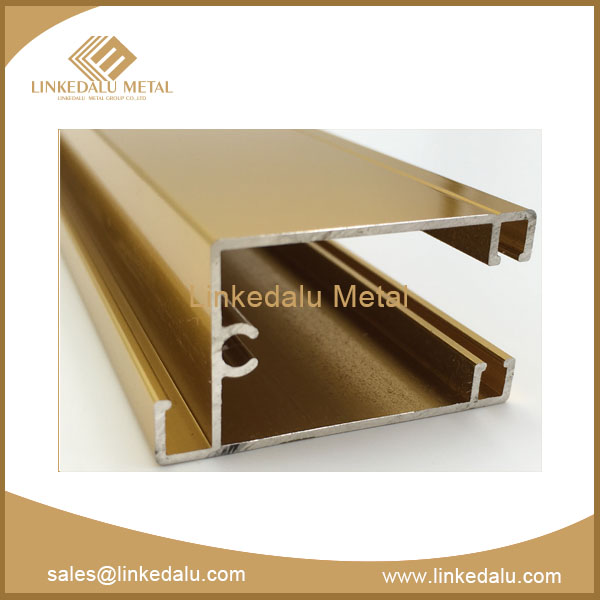

Curtain Wall Profiles

Curtain Wall Profiles

Windows and Doors Profiles

Windows and Doors Profiles