There are also electronic machinery industry and clean room frames. We are also an aluminium extrusion suppliers.

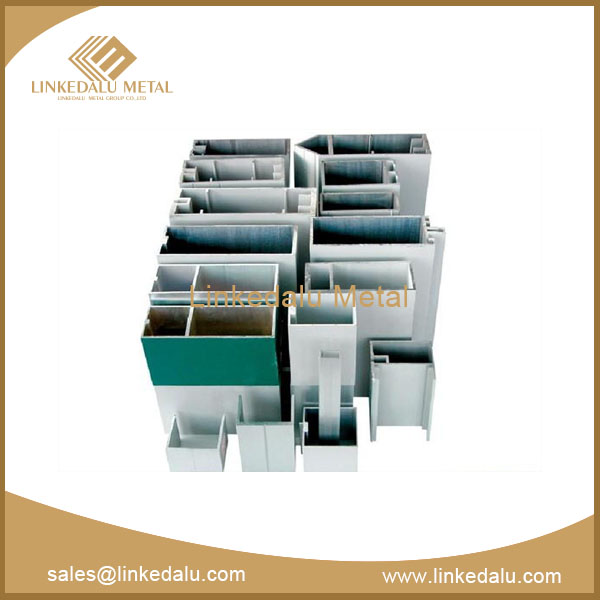

The assembly line aluminum profile is a structural aluminum profile with relatively high strength. A variety of industrial aluminum profile can be spliced into various shapes without welding, and the installation is relatively simple, convenient and quick, and the structure is also beautiful. The more prominent feature is that it can be spliced into different shapes without welding, so the assembly speed is fast, the appearance is beautiful, and the time is saved. In addition, it is light in weight, good in formability, high in strength and resistant to corrosion.

Recyclable features are also popular among users. Include aluminum framing system and aluminum curtain wall. Now extruded aluminium sections is very common. The assembly line aluminum profile is the industrial aluminum profile used in the production line of the workshop. In fact, many pipeline equipments are made of iron or steel. In general, the use of the assembly line aluminum profile has many advantages over all other materials. We are also an aluminium extrusion suppliers.

After the surface of the industrial aluminum profile is oxidized, the appearance is very beautiful, and it is resistant to dirt. Once it is coated with oil, it is very easy to clean. When assembled into a product, different profiles are used according to different load-bearing materials, and the matching aluminum profile fittings are used, and welding is not required. It is more environmentally friendly, and it is easy to carry and move with ease of installation and disassembly. Nowadays, the application of the assembly line aluminum profile frame is more and more extensive. The assembly line aluminum profile is used on the assembly line equipment at the beginning. As the frame part of the equipment, it has now developed into various types of automation equipment, frames, worktables, Testing equipment, industrial fences, dust-free sheds, etc. The assembly line aluminum profile is a structural aluminum profile with relatively high strength. Include aluminum framing system and aluminum curtain wall. A variety of industrial aluminum profile can be spliced into various shapes without welding. The installation is relatively simple, convenient and quick, and the structure is also beautiful. The more prominent feature is that it can be spliced into different shapes without welding, so the assembly speed is fast, the appearance is beautiful, and the time is saved. In addition, the light weight, good formability, high strength, corrosion resistance, and recyclability are also popular among users. Therefore, the assembly line industrial aluminum profile occupy a large share in today's profile market, and the application scenarios are also very extensive. Now extruded aluminium sections is very common.

©Copyright ©2020 LINKEDALU METAL GROUP CO.,LTD.Technical support:Guangzhou Jumi Network

All Products

All Products

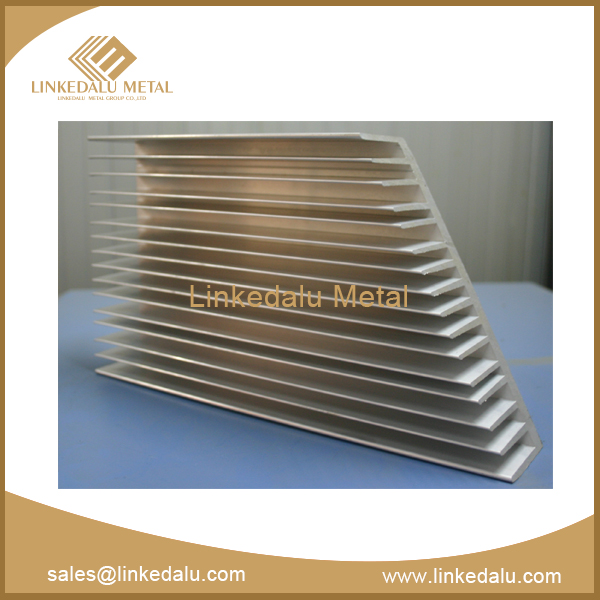

Industrial Profiles

Industrial Profiles

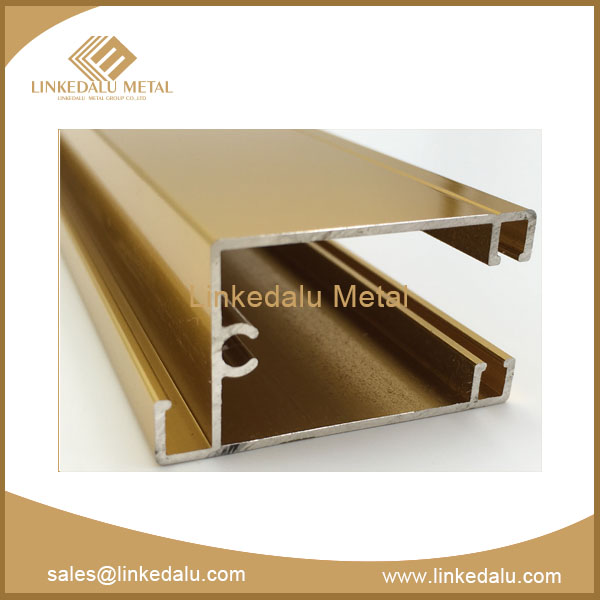

Curtain Wall Profiles

Curtain Wall Profiles

Windows and Doors Profiles

Windows and Doors Profiles