©Copyright ©2020 LINKEDALU METAL GROUP CO.,LTD.Technical support:Guangzhou Jumi Network

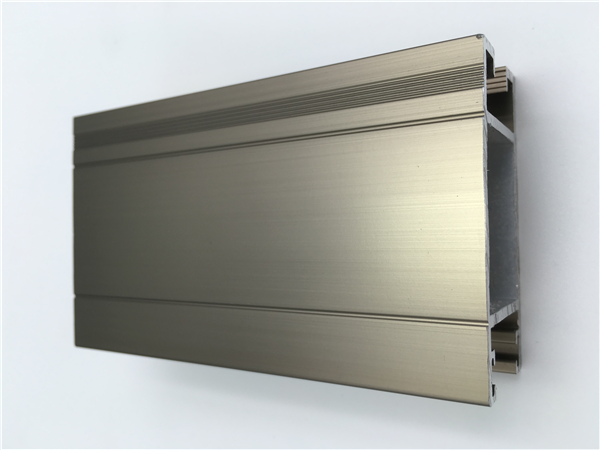

The common defects appearing on the aluminum extrusion are blister and peeling. The blister is convex on the surface of the aluminum extrusion, commonly in the head and tail parts. And peeling refers to the phenomenon that the surface blister has been broken.

A. Causes of blister and peeling

1. Extrusion cylinder and dummy block wear out seriously, leading unmatched sizes between the extrusion cylinder and dummy block of which the diameter difference exceeds the allowable value;

2. Extrusion cylinder and dummy block is unclean with oil, moisture, graphite and so on;

3. Lubricants contain water;

4. The shovel grooves are too deep or too many on the ingot surface, or there are pores, trachoma, loose tissue, oil on the ingot surface.

5. The cylinder is not clean in the alloy replacement.

6. Extrusion cylinder temperature and extrusion ingot temperature is too high;

7. The ingot temperature and size exceeds the allowable negative deviation;

8. Due to the long size, the fast filling and uneven temperature of the ingot, causing non-drum filling, the cylinder exhaust is not complete; or due to improper operation, the exhaust process does not work;

9. Due to the unreasonable design of the mold holes or improper residual material cutting, the residual material in the portholes and diversion holes is brought out, and the air gets into the surface during extrusion.

B. Measures to eliminate

1. Be delicate with the design of size of extrusion cylinder and dummy blocks; check the tools’ size regularly to meet requirements; and timely repair the cylinder when belly up; adopt the qualified dummy block;

2. Keep the surface of the tools and ingot to keep clean, smooth and dry;

3. Thoroughly clear cylinder when replace the alloy;

4. Regularly check the machines and equipments to prevent over-heat temperature and high speed.

5. Strictly implement according to the technical procedures and the system;

6. Reasonably design and manufacture the molds, ensuring the portholes and diversion holes a 1 ° -3 ° inner slope;

7. Strictly operate the cutting of the residue and the complete exhaust.

contact us

LINKEDALU METAL GROUP CO.,LTD.

We provide customers with quality products and provide high-quality services.