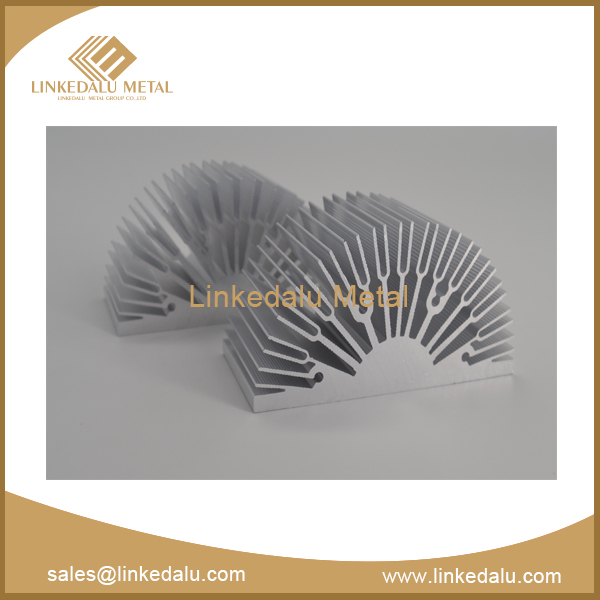

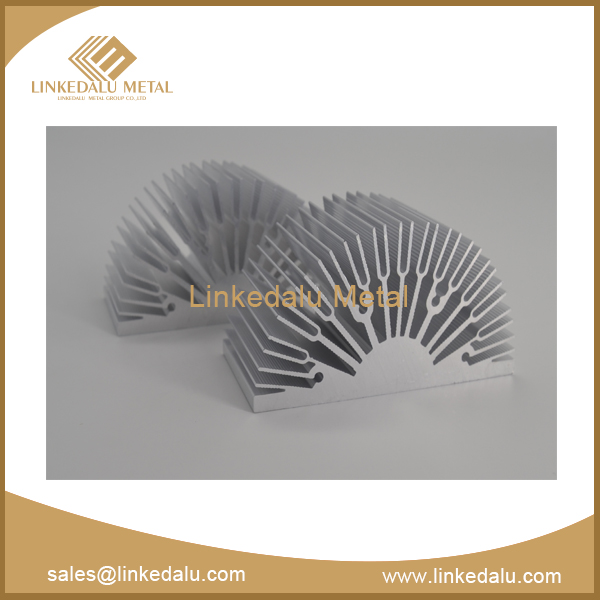

Description

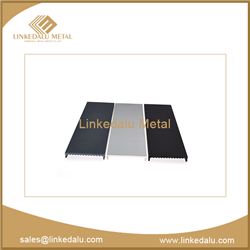

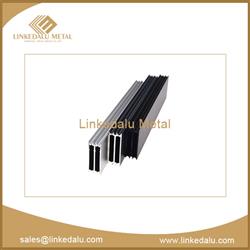

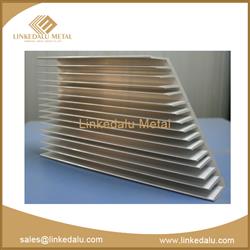

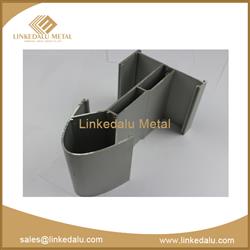

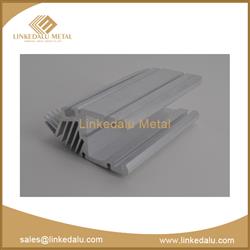

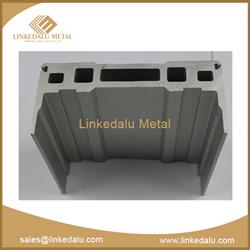

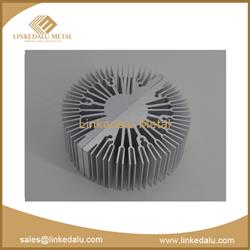

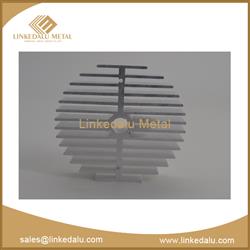

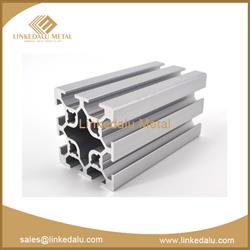

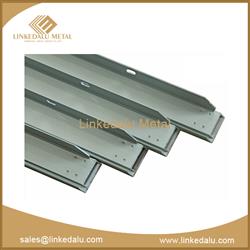

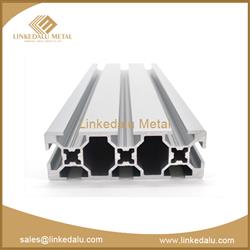

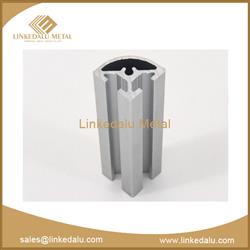

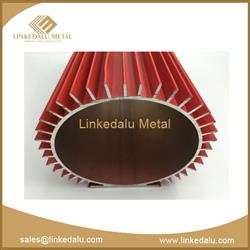

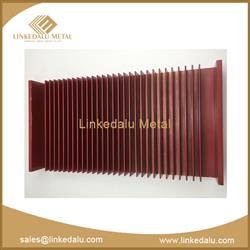

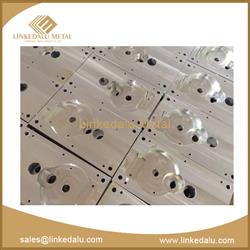

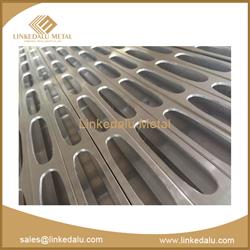

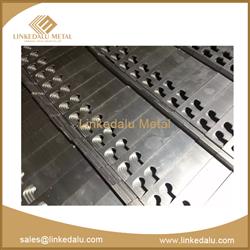

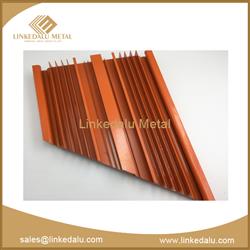

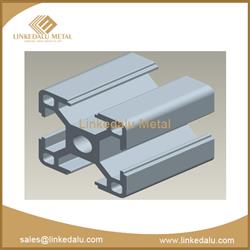

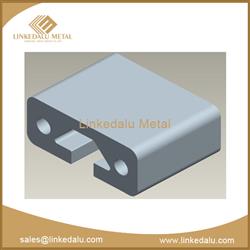

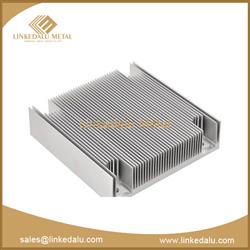

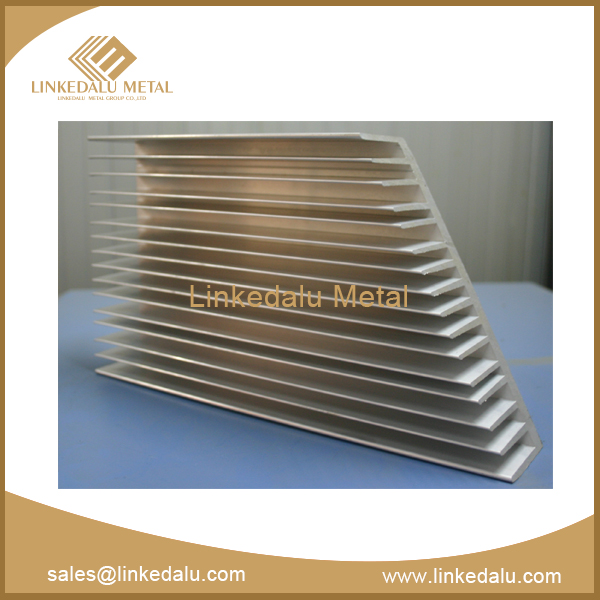

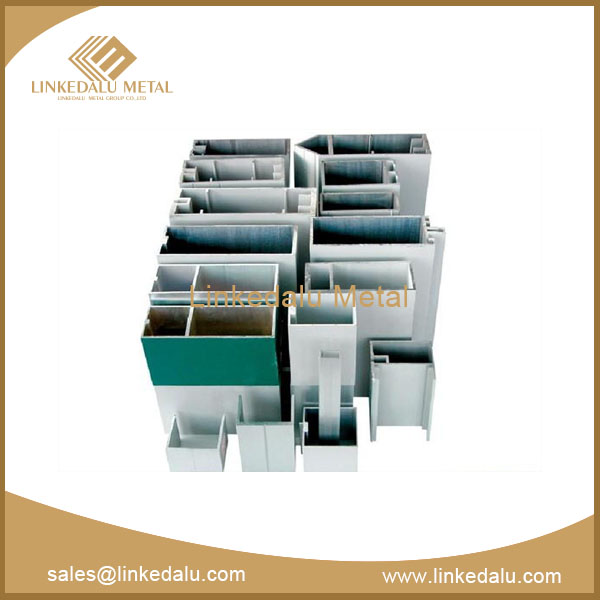

Industrial aluminum extrusions is an extensive field which cover those aluminum profiles used for heatsink, mechanical parts, scaffold etc. This kind of aluminum extrusions have specially requirement generally, we have professional engineer and skilled staff to meet the customers’ demand. Meanwhile, we also have CNC, Punching machines to make fabricated process.

Our advantages

1.against Chinese largest alumina mine to keep good material.

2.professional engineers and skilled workers.

3.one-stop aluminium extrusions and machining parts.

4.professional management to support our customers.

5.strict quality management system.

The procedure of procurement

1.Customers send samples or drawings to us to make our drawings.

2.Customers confirm drawings and pay for mould costs.

3.We need about 20 days to make moulds and send samples to customers approve.

4.Customers place order and pay for 30% deposit by T/T.

5.It takes about 20 days to finish an order to load container.

6.Customers pay for balance to get original documents.

FAQs

1.How many extrusion machines do you have and how many tons output every month?

We have 26 machines in two factories, and there are over 5000 tons output capability every month.

2.If you only produce aluminum extrusions?

We produce aluminum extrusions and machining products.

3.How many tons of the biggest press?

The biggest press is 3600tons.

The Unreplaceable Conditions of The Powerful Aluminium Extrusion Suppliers

As an economic and environmental protection product, aluminum profile has received a lot of people's pursuit. But the survival of the fittest, with the rapid development of society, industrial aluminum profiles also began to look for a new way out. After nearly 10 years of rapid growth, China's xxx has entered a new stage of development and has shown many new development trends. In terms of capacity distribution, there are about 95 countries and regions in the world that can produce industrial aluminum profiles in 2009, and there are about 2200 manufacturing enterprises. Among them, China's capacity accounts for more than 50% of the world's total capacity. From the perspective of application field, the construction industry is still the main application field of industrial aluminum profiles, far exceeding the consumption of other fields. The consumption volume has increased year by year, accounting for more than 63% of the total consumption by 2009. However, in recent years, the number of domestic Aluminium extrusion suppliers has been reduced from more than 1200 in the peak period to more than 680. Taking the industrial aluminum profiles produced in Jiangsu, Zhejiang and other regions as an example, a large number of Aluminium extrusion suppliers products with low technical level, poor quality and low grade have been gradually eliminated, and the restructuring and integration of the industry will become a major trend in the future. The aluminum alloy extrusion industry has crossed the primary development stage characterized by quantity growth and entered a new stage of market competition relying on technological innovation and comprehensive strength. Therefore, qualified Aluminium extrusion suppliers should have some conditions to help them improve the output of product quality and capacity. The quality and price of aluminum profiles produced by a powerful Aluminium extrusion suppliers and an average Aluminium extrusion suppliers are very different. These conditions mainly include the following three aspects:

1. High quality industrial aluminum extrusion production line

Aluminum extrusion production line is the composition of equipment and production personnel. A strong Aluminium extrusion suppliers needs at least 5 ~ 8 imported advanced extrusion production lines and at least 10 extrusion equipment. Each production line has at least 3 personnel. Ensure that each production line can be automated under the supervision of personnel.

2. Extrusion technology control of high quality industrial aluminum profiles

Extrusion technology of industrial aluminum profiles is one of the necessary conditions for producing high quality aluminum profiles. Aluminium extrusion suppliers, with high comprehensive strength, has a special technical engineering department, which analyzes the profile section to be extruded, compares and analyzes each equipment and each production line. Using advanced equipment and advanced technology to produce high quality products.

3. Extrusion capacity and quality inspection of high quality industrial aluminum profiles

Aluminium extrusion suppliers's production line is complete, and the staffing is also complete, so the extrusion capacity is naturally guaranteed. But is it possible to produce high quality aluminum profiles with extrusion capability. The answer is no! Because, if there is no perfect quality inspection, the extrusion process is also damaged. Inspection from raw material inspection, production inspection and subsequent factory inspection, this series of procedures to ensure high-quality aluminum profile production.

All Products

All Products

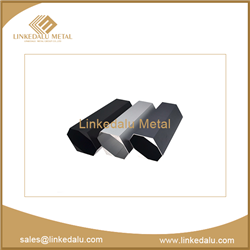

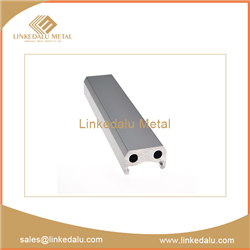

Industrial Profiles

Industrial Profiles

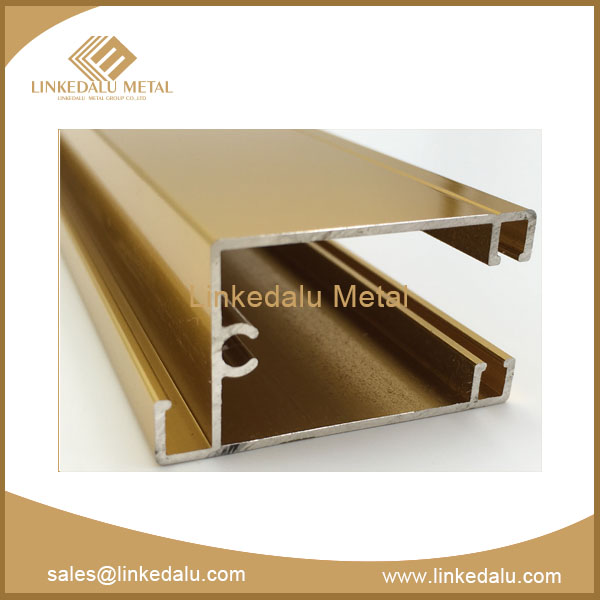

Curtain Wall Profiles

Curtain Wall Profiles

Windows and Doors Profiles

Windows and Doors Profiles